To enable error-checking, it is good practice to place markers within the input file. Markers are simple statements to be output to the screen using the puts tcl command. These markers tell the user what commands have been completed. This way, if an error occurs, the user is able to find the location of the error. Here is an example, where puts commands are placed here and there in the input1.tcl file:

puts "Begin units defintion"

# DEFINE UNITS

set in 1.; # define basic unit -- length

set sec 1.; # define basic unit -- time

set kip 1.; # define basic unit -- weight (or define force, but not both)

set ksi [expr $kip/pow($in,2)]; # define engineering units

set psi [expr $ksi/1000.];

set ft [expr 12.*$in];

set g [expr 32.2*$ft/pow($sec,2)]; # gravitational acceleration

set PI [expr 2*asin(1.0)]; # define constants

set U 1.e10; # a really large number

set u [expr 1/$U]; # a really small number

puts "Units have been defined"

# define GEOMETRY variables

set Hcol [expr 6.*$ft]; # column diameter

set Lcol [expr 36*$ft]; # column length

set GrhoCol 0.015; # column longitudinal-steel ratio

set Weight [expr 3000.*$kip]; # superstructure weight

set Rcol [expr $Hcol/2]; # COLUMN radius

set Acol [expr $PI*pow($Rcol,2)]; # column cross-sectional area

set cover [expr $Hcol/15]; # column cover width

set G $U; # Torsional stiffness Modulus

set J 1.; # Torsional stiffness of section

set GJ [expr $G*$J]; # Torsional stiffness

# define COLUMN REINFORCEMENT variables

set NbCol 20; # number of column longitudinal-reinforcement bars

set AsCol [expr $GrhoCol*$Acol]; # total steel area in column section

set AbCol [expr $AsCol/$NbCol]; # bar area of column longitudinal reinforcement

# define GRAVITY variables

set Mass [expr $Weight/$g]; # mass of superstructure

set Mnode [expr $Mass]; # nodal mass for each column joint

# define DAMPING variables from $xDamp --SDOF system, use stiffness proportional damping only

set xDamp 0.02; # modal damping ratio

# ------ set analysis variables

set DxPush [expr 0.1*$in]; # Displacement increment for pushover analysis

set DmaxPush [expr 0.05*$Lcol]; # maximum displamcement for pushover analysis

set gamma 0.5; # gamma value for newmark integration

set beta 0.25; # beta value for newmark integration

set DtAnalysis [expr 0.005*$sec]; # time-step Dt for lateral analysis

set DtGround [expr 0.02*$sec]; # time-step Dt for input grond motion

set TmaxGround [expr 50.*$sec]; # maximum duration of ground-motion analysis

puts "All inital variables have been defined"

# define ModelBuilder

model basic -ndm 2 -ndf 3; # basic: modelbuilder type, ndm= number of dimensions, ndf= #dof/node

puts "the Model has been built"

# Nodal Coordinates and Nodal Masses

node 1 0. 0.; # column base is located at the origin of the plane

node 2 0. $Lcol -mass $Mnode 0. 0.; # the column end has one translational mass in the x direction, only

# Boundary Conditions

fix 1 1 1 1; # fixed base

fix 2 0 0 0; # free end

puts "Nodal Coordinates, Nodal Masses, and Boundary Conditions have been defined"

puts "Begin material definition"

# Confined concrete:

set fc [expr -5.5*$ksi]; # CONCRETE Compressive Strength, ksi (+Tension, -Compression)

set Ec [expr 57*$ksi*sqrt(-$fc/$psi)]; # Concrete Elastic Modulus

set fc1C [expr 1.26394*$fc]; # CONFINED concrete (mander model), maximum stress

set eps1C [expr 2.*$fc1C/$Ec]; # strain at maximum stress

set fc2C $fc; # ultimate stress

set eps2C [expr 5*$eps1C]; # strain at ultimate stress

# Unconfined concrete:

set fc1U $fc; # UNCONFINED concrete (todeschini parabolic model), maximum stress

set eps1U -0.003; # strain at maximum stress

set fc2U [expr 0.1*$fc]; # ultimate stress

set eps2U -0.006; # strain at ultimate stress

# Concrete02 variables:

set lambda 0.1 ; # ratio between unloading slope at $epscu and initial slope

set ftC [expr -$fc1C/10.]; # tensile strength +tension

set ftU [expr -$fc1U/10.]; # tensile strength +tension

set Ets [expr $Ec/10.]; # tension softening stiffness

# reinforcing steel

set Fy [expr 68.*$ksi]; # STEEL yield stress

set Es [expr 29000.*$ksi]; # modulus of steel

set epsY [expr $Fy/$Es]; # steel yield strain

set Fu [expr 95.2*$ksi]; # ultimate stress of steel

set epsU 0.1; # ultimate strain of steel

set E2 [expr ($Fu-$Fy)/($epsU-$epsY)]; # post-yield tangent stiffness

set Bs [expr $E2/$Es]; # post-yield stiffness ratio of steel

# set up parameters for column section and element definition

set IDcore 1; # ID tag for core concrete

set IDcover 2; # ID tag for cover concrete

set IDsteel 3; # ID tag for steel

puts "All material variables have been defined"

uniaxialMaterial Concrete02 $IDcore $fc1C $eps1C $fc2C $eps2C $lambda $ftC $Ets; # CORE CONCRETE

uniaxialMaterial Concrete02 $IDcover $fc1U $eps1U $fc2U $eps2U $lambda $ftU $Ets; # COVER CONCRETE

uniaxialMaterial Steel01 $IDsteel $Fy $Es $Bs; # REINFORCING STEEL

puts "All materials have been defined"

puts "Being element cross-section definition"

# element cross-section

# Notes

# The center of the reinforcing bars are placed at the inner radius

# The core concrete ends at the inner radius (same as reinforcing bars)

# The reinforcing bars are all the same size

# The center of the section is at (0,0) in the local axis system

# Zero degrees is along section y-axis

set IDcolFlex 2; # ID tag for column section in flexure, before aggregating torsion

set riCol 0.0; # inner radius of column section

set roCol $Rcol; # outer radius of column section

set nfCoreR 8; # number of radial fibers in core (number of "rings")

set nfCoreT 16; # number of tangential fibers in core (number of "wedges")

set nfCoverR 2; # number of radial fibers in cover

set nfCoverT 16; # number of tangential fibers in cover

# cover - cover thickness, has been defined with the geometry

# IDcore - material tag for the core patch, has been defined with the materials

# IDcover - material tag for the cover patches, has been defined with the materials

# IDsteel - material tag for the reinforcing steel, has been defined with the materials

# NbCol # number of column longitudinal-reinforcement bars, has been defined with the geometry

# AbCol # bar area of column longitudinal reinforcement, has been defined with the geometry

puts "All element-cross-section variables have been defined"

puts "Begin section definition"

section fiberSec $IDcolFlex {

set rc [expr $roCol-$cover]; # Core radius

patch circ $IDcore $nfCoreT $nfCoreR 0 0 $riCol $rc 0 360; # Define the core patch

patch circ $IDcover $nfCoverT $nfCoverR 0 0 $rc $roCol 0 360; # Define the cover patch

puts "All patches have been defined"

set theta [expr 360.0/$NbCol]; # Determine angle increment between bars

layer circ $IDsteel $NbCol $AbCol 0 0 $rc $theta 360; # Define the reinforcing layer

puts "All layers have been defined"

}

puts "End of element-cross-section definition"

puts "Begin Element Connectivity"

# element connectivity

set IDcolTors 10; # ID tag for column section in torsion

set IDcolSec 1; # ID tag for column section

uniaxialMaterial Elastic $IDcolTors $GJ; # Define torsional stiffness

section Aggregator $IDcolSec $IDcolTors T -section $IDcolFlex; # attach torsion to flexure and create a new section IDtag

puts "All has been aggregated"

set IDcolTrans 1; # ID tag for column transformation, defining element normal

geomTransf Linear $IDcolTrans; # Linear: no second-order effects

set np 5; # Number of integration points

element nonlinearBeamColumn 1 1 2 $np $IDcolSec $IDcolTrans

puts "End Element defintion"

puts "Begin Gravity loads"

# apply constant gravity load (and other constant loads)

set Pdl [expr $Weight]; # gravity axial load per column

pattern Plain 1 Linear {

load 2 0.0 -$Pdl 0.0

}

puts "Gravity Load Pattern has been defined"

# set up solution procedure

system UmfPack; # solution procedure, Super-LU, how it solves system of equations

constraints Plain; # how it handles boundary conditions, enforce constraints through the transformation

# set up convergence criteria

test NormDispIncr 1.0e-5 10 0; # tolerance, max no. of iterations, and print code , 1: every iteration

algorithm Newton; # use Newton's solution algorithm: updates tangent stiffness at every iteration

numberer RCM; # renumber dof's to minimize band-width (optimization)

# set up load steppring

integrator LoadControl 0.1 1 0.1 0.1; # variable load-stepping

# set up type of analysis, static for gravity

analysis Static

puts "Static Analysis for Gravity and Constant loads has been defined"

initialize

# RUN GRAVITY ANALYSIS

analyze 10

loadConst -time 0.0

puts "End of Gravity Analysis"

# print to screen that you are done with this step:

puts "Done with Structural Model Generation"

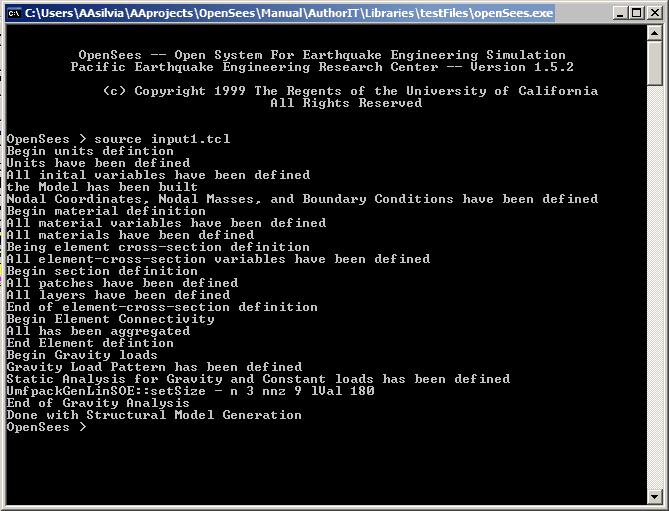

The OpenSees control window will look like this:

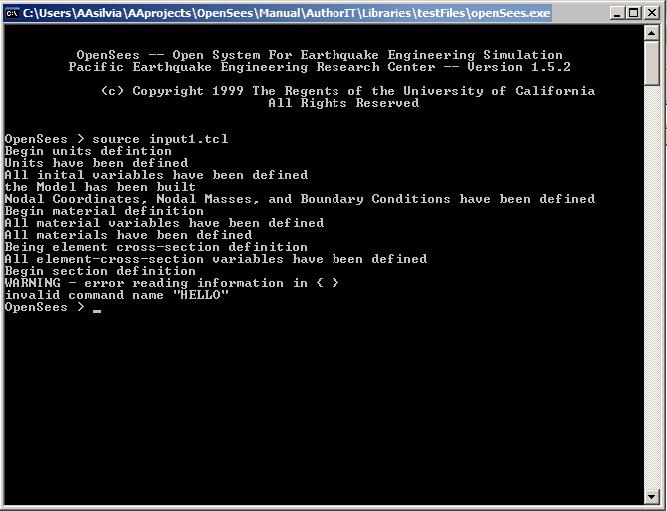

When there is an error, it can be localized:

Based on the markers, the erroneous command is located within the section definition, between the two puts commands.

puts "Begin section definition"

section fiberSec $IDcolFlex {

set rc [expr $roCol-$cover]; # Core radius

patch circ $IDcore $nfCoreT $nfCoreR 0 0 $riCol $rc 0 360; # Define the core patch

HELLO

patch circ $IDcover $nfCoverT $nfCoverR 0 0 $rc $roCol 0 360; # Define the cover patch

puts "All patches have been defined"

set theta [expr 360.0/$NbCol]; # Determine angle increment between bars

layer circ $IDsteel $NbCol $AbCol 0 0 $rc $theta 360; # Define the reinforcing layer

puts "All layers have been defined"

}